|

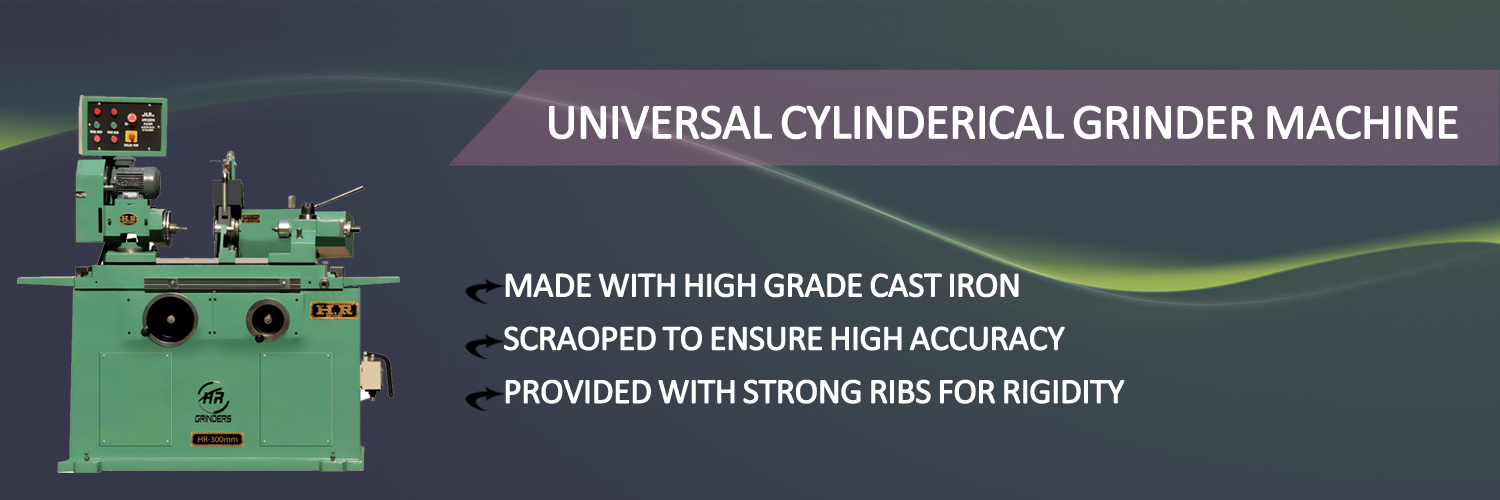

SPECIFICATIONS : |

HR-1 |

HR-2 |

HR-3 |

|

Maximum Grinding Length |

300mm, |

450mm, |

600mm, |

|

Maximum Hight of Centers |

145mm, |

145mm, |

145mm, |

|

Maximum Swig over table |

250mm, |

290mm, |

290mm, |

|

Maximum grinding diameter |

200mm, |

240mm, |

240mm, |

|

Table feed |

-------- |

Hyd/Mech |

Hyd/Mech |

|

Range of table feeds per minute |

In Hydraulic

infinitely In Hydraulic infintely

variable/In mechanical |

100-175-275mm. |

|

Maximum table e swivel |

9 + 3 -12 |

9 + 3 - 12 |

9 + 3 - 12 |

|

Work head swivel on either side |

90 / 30 |

90 / 30 |

90 / 30 |

|

Work Spindle speeds |

3 |

4 |

4 |

|

Work

Spindle speeds range |

50 to 100 |

60 to 350 |

60 to 350 |

|

Taper in work

spindle |

MT-3 |

MT-4 |

MT-4 |

|

Taper in tailspindle |

MT-3 |

MT-4 |

MT-4 |

|

To and fro swivel of wheel head |

60 |

60 |

60 |

|

Transverse movement of wheel head max |

125mm. |

125mm. |

125mm. |

|

Size of Grinding wheel |

355X38X127mm. |

355X38X127mm. |

355X38X127mm. |

|

Min, dia of worn out wheel |

225mm. |

225mm. |

225mm. |

|

R.P.M. of Grinding wheel (Two Range) |

1650/2200 |

1650/2200 |

1650/2200 |

|

Maximum Internal Grinding depth |

80mm |

80mm |

100mm |

|

Min & Max. dia of hole for grinding |

15 to 240mm. |

15 to 240mm. |

15 X 240mm. |

|

Wheel Head motor 14440 R.P.M |

3 H. P . |

3 H. P . |

3 H. P . |

|

Work Head motor 960 R.P.M. |

0.75 HP. |

0.75 HP. |

0.75 HP. |

|

Motor For table drive Hyd./Mech. |

2 H.P 0.75 H.P. |

2 H.P 0.75 H.P. |

2 H.P 0.75 H.P. |

|

Motor for internal grinding attachment |

0.75 H.P. |

0.75 H.P. |

0.75 H.P. |

|

Approximate weight with packing |

1200 Kg |

1400 Kg |

2000 Kg |

|

STANDARD EQUIPMENT :Coolant Pump, Dressing Tool Holder

with Tool grinding wheel, Grease gun, Oil can, Dead Centres, Key

spanners, Wheel Flange. |

|

OPTIONAL EQUIPMENT : (At extra cost) Internal grinding

attachment (to be ordered with the machine) SELF CENTRING CHUCKS 5

Independent 4 jaw chucks 6” 3 POINT STEADY REST 2 POINT STEADY REST,

Revolving Centre, Radius truing device, Balancing Stand Balancing

Mandrel and spare wheel flange. (Right reserved for

thee changes towards improvement in Desing & Construction.) |